The Gowardhan factory was started in the year 1992. It is located in the milk belt of Manchar on the Mumbai Nashik highway. Unit 1, processes raw milk into processed pouch milk, curd, paneer, ghee, and shrikhand. The huge investment in infrastructure has enabled the unit to process up to almost 12 lakh litres of milk daily. The factory has employed around 600 fixed + daily wage workers. Thus, being the source of income for farmers in the neighbouring towns and villages.

The Gowardhan factory was started in the year 1992. It is located in the milk belt of Manchar on the Mumbai Nashik highway. Unit 1, processes raw milk into processed pouch milk, curd, paneer, ghee, and shrikhand. The huge investment in infrastructure has enabled the unit to process up to almost 12 lakh litres of milk daily. The factory has employed around 600 fixed + daily wage workers. Thus, being the source of income for farmers in the neighbouring towns and villages.

"We at Parag live and breathe our corporate slogan of Ideas for a new day." |

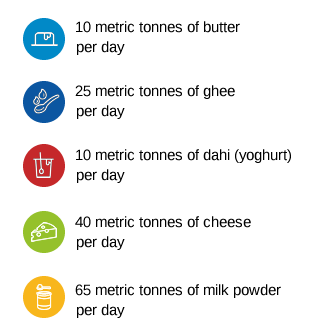

The Go Cheese factory was started in early 2000. It is located in the milk belt of Manchar on the Mumbai Nashik highway. The UHT technology is of international standards with the best European technology, fully automated and requires minimum human intervention. Right from reception of milk to the finished product, we maintain strict no-human-contact through the entire manufacturing process. Moreover, our plant is capable of churning out 1,000,000 litres of milk per day, has an output capacity up to 10 metric tonnes of butter, 25 metric tonnes of ghee, 10 metric tonnes of dahi (yoghurt), 40 metric tonnes of cheese and 65 metric tonnes of milk powder per day. The factory is quite often a part of study tours for school kids who learn the history & art of cheese making.

Another fascinating aspect of our plant is that it is one of the only two facilities in Asia with UHT technology. The equipment has been imported from Stephan Machinery Germany, pioneers in cheese processing equipment. The cheese can be stored in ambient condition without refrigeration up to a period of 6 months in tropical countries like India. The company is sure to reach national markets with its UHT treated, superior quality cheese, which will be available in a variety of forms such as slices, wedges spreads and an assortment of exciting flavours under a new brand name, Go.

"We aim to identify, elaborate and disseminate best practices at all our infrastructures." |

The Gowardhan plant was started in early 2010 at Chitoor, Palamner, town on the AP-Karnataka border. The idea was to cater to the south market with fresh cow milk. The plant is equipped with state of the art technology which packs milk & dairy products in tetra packs. The employee strength is 400+ thus helping farmers get a source of income through their livestock.

The Gowardhan plant was started in early 2010 at Chitoor, Palamner, town on the AP-Karnataka border. The idea was to cater to the south market with fresh cow milk. The plant is equipped with state of the art technology which packs milk & dairy products in tetra packs. The employee strength is 400+ thus helping farmers get a source of income through their livestock.

"Fulfilling dietary nutritional requirements is a source of great joy and creativity for us." |

Pride of Cows is a brand of Parag Milk Foods. It is regarded as India's most modern dairy farm with the finest international equipment that provides the customers with superior farm-to-home milk. It is strategically located in the milk belts at Manchar, Maharashtra and Palamner, Andhra Pradesh.

At Pride of Cows we ensure the cows well-fed and are eating well-balanced meals as per their nutritional needs and requirements, milk production, body weight, location and age. The idea is to pamper the cow because only when a cow is happy will it yield the necessary high quality milk. The parent company Parag Milk Food's product portfolio includes milk, skimmed milk powder, whole milk powder, ghee, processed cheese, butter, dahi, proprietary foods like dairy whitener and gulab jamun mix powder under the brand names of Go and Gowardhan.

"A key area of focus for us is to help farmers and milk producers to boost animal productivity." |